What Are You Looking For?

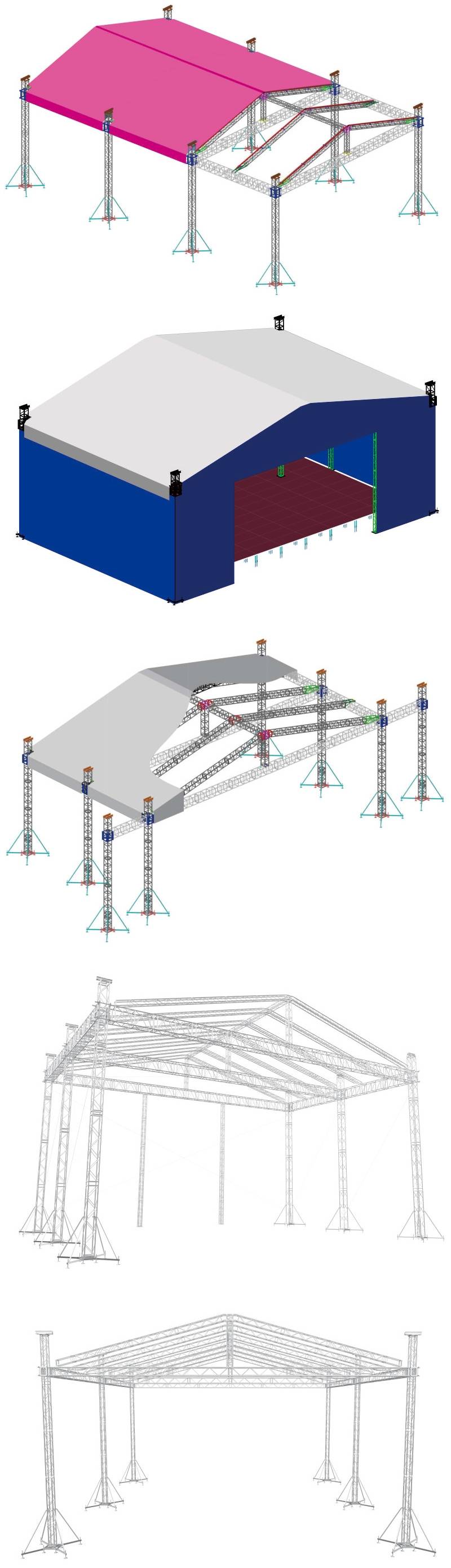

The design of aluminum outdoor concert curved roof trusses presents a complex interplay between structural integrity, aesthetic considerations, and practical requirements. By leveraging the inherent properties of aluminum, employing advanced analysis tools, and adopting innovative design approaches, engineers can create structures that offer both robust support and a visually captivating experience. As technology continues to advance, further refinements in design and materials will continue to enhance the performance and aesthetic appeal of curved roof trusses, solidifying their place as integral components of the outdoor concert experience.

The allure of outdoor concerts lies in the experience of music under the open sky. However, the need for protection from the elements and the creation of a visually appealing stage necessitate innovative structural solutions. Among these, curved roof trusses constructed from aluminum offer a compelling combination of strength, flexibility, and aesthetics, transforming open-air venues into dynamic and captivating spaces.

The Appeal of Aluminum:

Aluminum's properties make it an ideal material for outdoor concert truss construction. Its lightweight nature allows for the creation of expansive roof structures without placing undue stress on supporting columns or the ground. Aluminum's high strength-to-weight ratio ensures structural stability even in challenging weather conditions. Furthermore, its corrosion resistance and longevity make it an excellent choice for outdoor environments, minimizing maintenance requirements and extending the lifespan of the structure.

The Challenges of Curved Roof Design:

Curved roof trusses pose unique design challenges. Unlike traditional straight trusses, curved structures require careful consideration of the forces acting upon them. The curvature introduces bending and shear forces that need to be precisely calculated and addressed to ensure structural integrity. The complex geometry also necessitates advanced analysis tools and software to model the intricate load paths and stress distribution within the truss.

Designing for Structural Integrity:

The design of a curved roof truss for an outdoor concert stage begins with a thorough analysis of the site and the anticipated loads. This involves assessing factors like wind pressure, snow load, and the weight of the roof covering and any additional equipment. Engineers employ sophisticated software programs such as Finite Element Analysis (FEA) to model the structure and simulate its behavior under various load conditions. This analysis determines the optimal truss configuration, including the size, shape, and spacing of individual members, as well as the type and thickness of the aluminum used.

Optimizing Aesthetics:

While structural integrity is paramount, the design of a curved roof truss must also prioritize aesthetics to create an engaging and memorable concert experience. The curvature can be manipulated to create a sense of flow and dynamism, complementing the visual spectacle of the stage performance. The truss itself can be incorporated as a design element, with the aluminum surfaces offering opportunities for lighting integration, branding, and other visual effects.

Addressing Practical Considerations:

The design must also address practical considerations such as access, maintenance, and safety. Curved roof trusses often require specialized scaffolding and rigging for assembly and dismantling. The design should incorporate easy-to-access points for inspection and maintenance, ensuring the long-term performance and safety of the structure.

Case Studies and Innovations:

Numerous examples demonstrate the effectiveness of aluminum curved roof trusses in outdoor concert venues. The Coachella Valley Music and Arts Festival, for instance, features expansive curved roof structures that provide shade and shelter for attendees, while also creating a visually striking architectural statement. Innovative design approaches like the use of prefabricated truss components and modular construction techniques expedite assembly and dismantle processes, enhancing efficiency and minimizing downtime.